At Chemiesynth, we offer flexible, end-to-end chemical manufacturing services, from lab-scale development to commercial production.

Core Chemistry Expertise

We support a wide range of advanced chemical reactions :

- Acetylation

- Amination

- Bromination

- Chlorosulphonation

- Diazotization

- Esterification

- Etherification

- Friedel–Crafts Reactions

- Nitration

- Nitrosation

- Sulphonation

- Vilsmeier Reaction

- Oxidation

- Reduction

- Multi-Stage Synthesis

Hydrogenation (using precious metals)

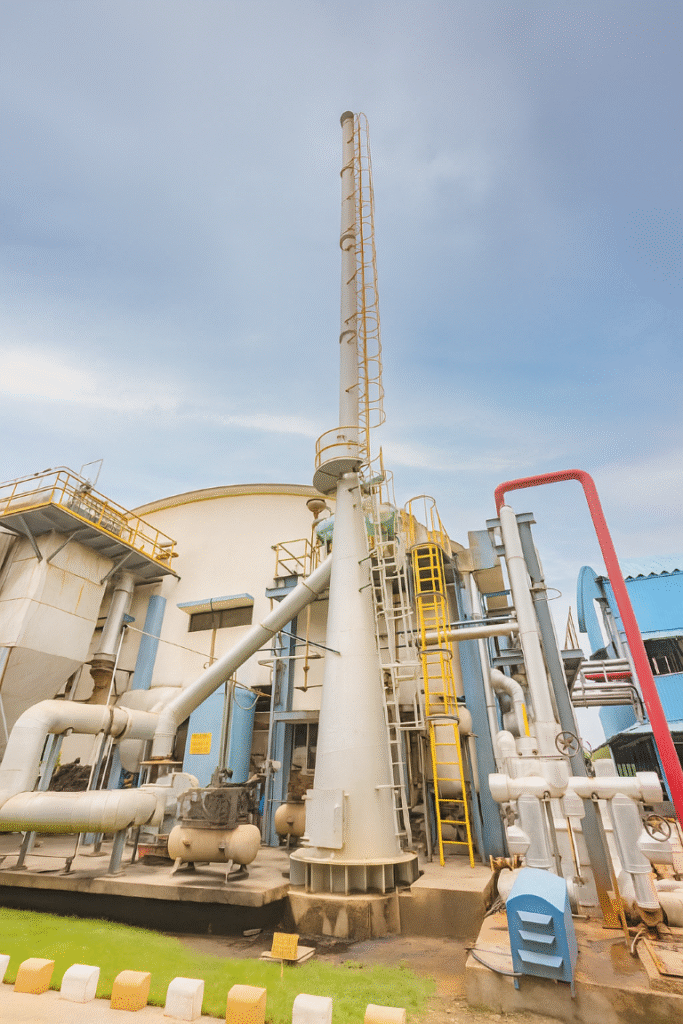

Infrastructure & Facilities

Reactor Capacity

600+ KL total

Pressure Reactors & Hydrogenation

Distillation

Solids Handling & Drying

Utilities & Process Support

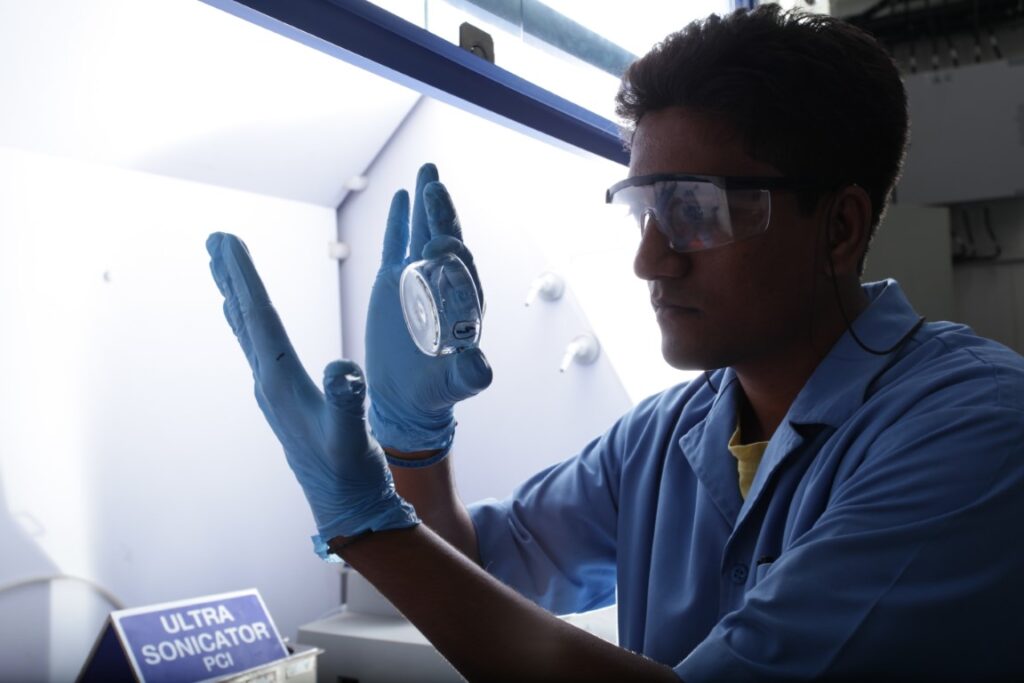

Quality Control & R&D Integration

Our operations are backed by fully equipped on-site QC labs and a dedicated R&D team that supports:

- Process development & optimization

- Scale-up from lab to plant

- In-process and final product testing

- Documentation & regulatory support (as needed)

Every batch is manufactured with a focus on precision, consistency, and compliance.